Tel:+8615962749608

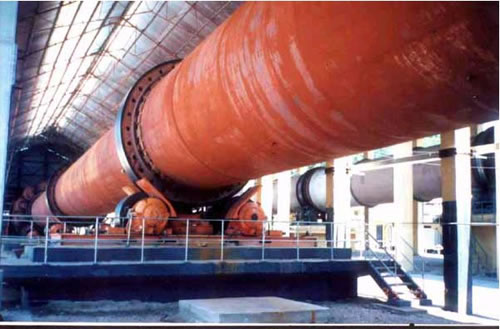

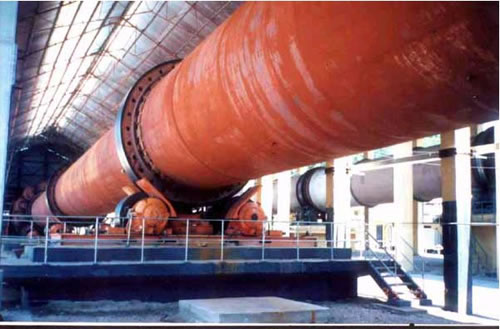

Working Principles:

The filtered titanium dioxide hydrolysate is sent to the tail of titanium dioxide rotary kiln with certain inclination. The combustion mixing chamber at the end of kiln head can send clean flame and hot air into the kiln body to dehydrate and calcine filter cake. After the hydrolyzed titanium dioxide filter cake has been hydrated at a temperature more than 1000℃, and calcined, under the help of titanium dioxide rotary kiln, it can roll along the circumferential direction as well as move along the axial direction from the high end to lower end until it finally finishes dehydration and calcination. Finally, the dehydrated and calcined titanium dioxide will be sent to a cooler through the double hydraulic discharge valve. The cooled and screened material is final titanium dioxide products.

Technical Parameters:

Note: Parameters in the form are only for reference, and specific ones need referring to particular contract.